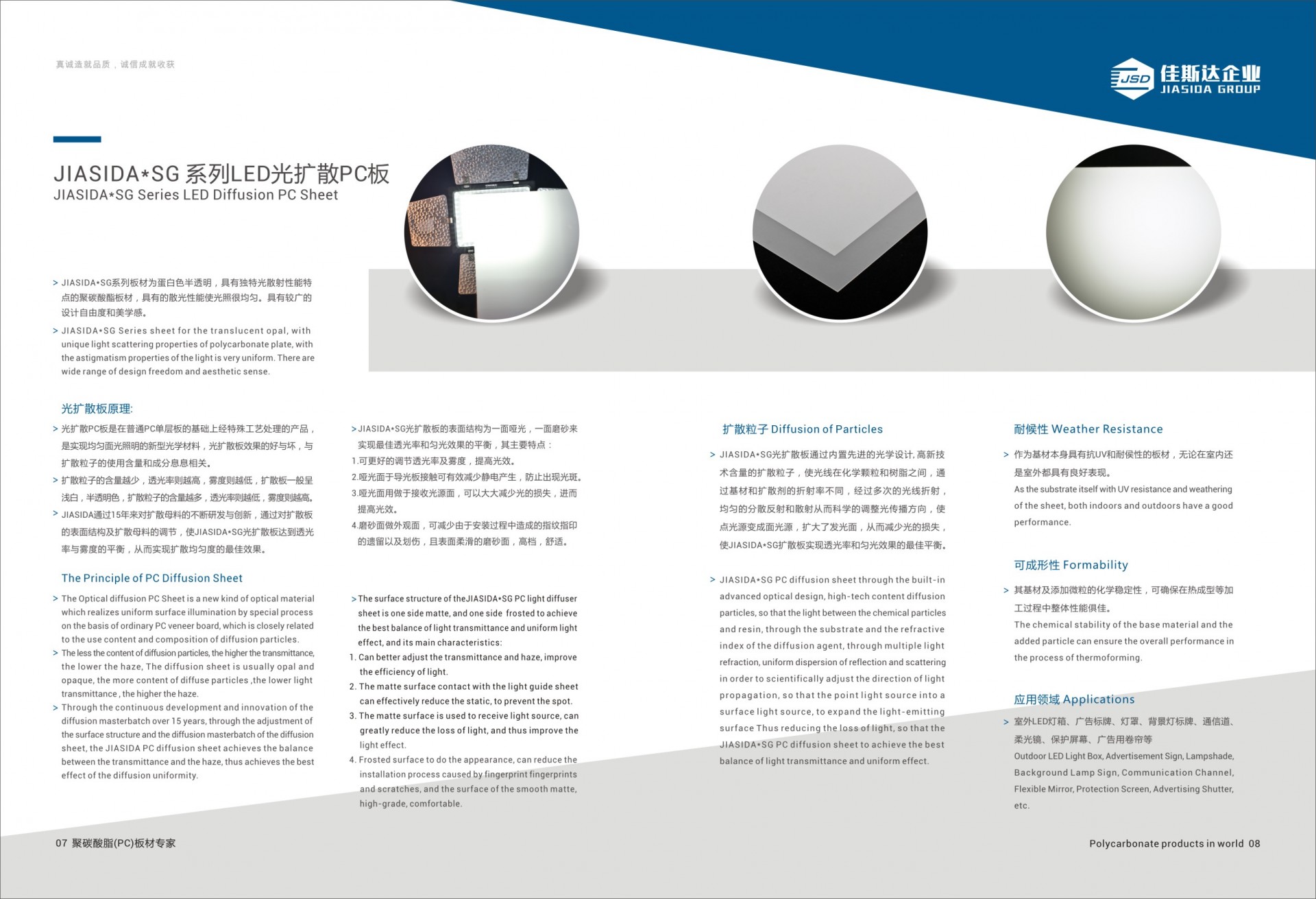

ZHENGSHUN*SG Series Diffusion Polycarbonate Sheet

Zhengshun *SG Series Sheet for the translucent opal, with unique light scattering properties of polycarbonate sheet,with the astigmstism properties of the light is very uniform.There are wide range to design freedom and aesthetic sense.

The principle of Polycarbonate Diffusion Sheet

The principle of Polycarbonate Diffusion Sheet

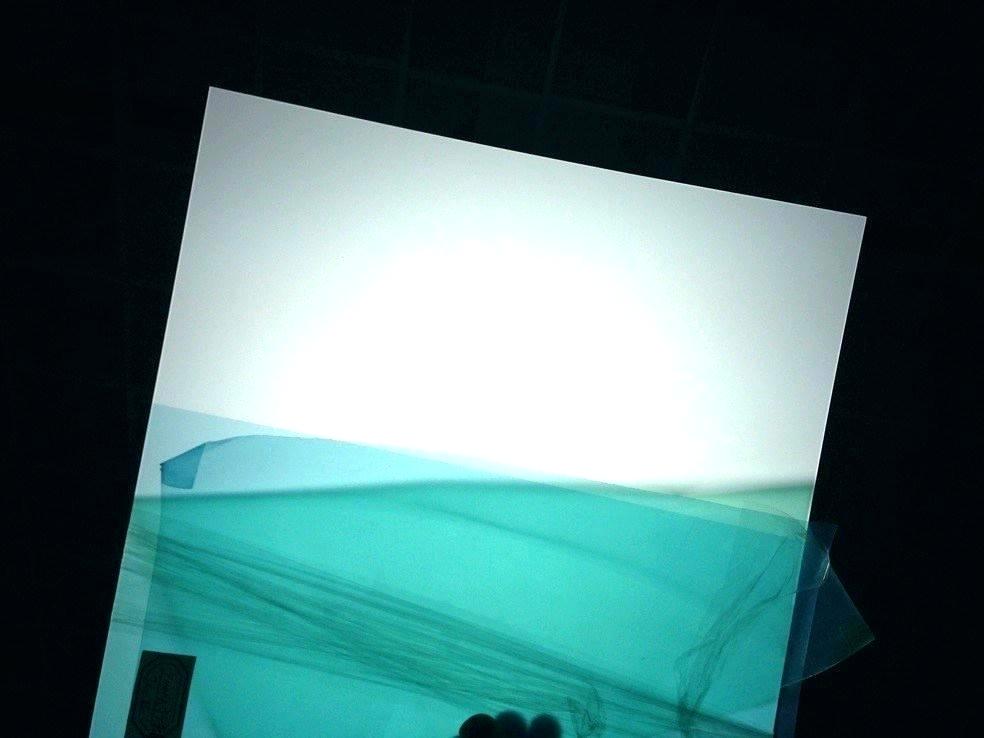

The Optical Polyarbonate diffusion sheet is a new kind of optical material which realizes uniform surface illumination byspecial process on the basisi of ordinary PC veneer board,which is closely related to use content and composition of diffusion particles.

The less the content of diffusion particles, the higher the transmittance,the lower the haze, the diffusion sheet is usuallyopal and opaque,the more content of diffusion particles,the lower light transmittance,the higher the haze.

Through the continuous development and innovation of the diffusion masterbatch over 15 years,through the adjustment of the surface structure and the diffusion masterbatch of the diffusion sheet,the PC diffusion sheet achieves the balance between the transmittance and the haze,thus achieves the best effect of the diffusion uniformity.

The Surface structrue of PC light diffuser sheet is one side matte,and one side frosted to achieve the best balance of the light trasmittance and uniform light effect,and its main characteristics.

1.Better adjust the transmittance and haze,improve the efficicency of light .

2.the matte surface contact with the light guide sheet can effectively reduce the static,to prevent the spot.

3.The matte surface is used to receive light source,can greatly reduce the loss of light ,and thus improve the light effect

4.Frosted surface to do the appearance, reduce the installation process caused by fingerprint fingerprints and scratches,and the surface of the smooth matte,high-grade comfortable.

| Product Model | Surface Texture | color | Thickess Range | Standard Thickness |

| Zhengshun*SG11WO | both sides polished | white | 0.5mm-10mm | 1mm/1.mm/1.5mm/2mm/3mm |

| Zhengshun*SG41WO | one side velvet,one side polished | white | 0.5mm-6mm | 1mm/1.mm/1.5mm/2mm/3mm |

| Zhengshun*SG42WO | one sider velvet,one side matte | white | 0.5mm-3mm | 1mm/1.mm/1.5mm/2mm/3mm |

| Zhengshun*SG31WO | one side fine velvet,one side polished | white | 0.5mm-3mm | 1mm/1.mm/1.5mm/2mm/3mm |

| Zhengshun*SG44WO | both sides velvet | white | 0.5mm-3mm | 1mm/1.mm/1.5mm/2mm/3mm |

| Zhengshun*SG**HT | / | light white | 0.5mm-3mm | 1mm/1.mm/1.5mm/2mm/3mm |

| Zhengshun*SG*W-F | / | white | UL-94V0 Flame retardant PC diffuser sheet |

| Item | Unit | Detectiion Method | Index |

| Specific Gravity | Kg/mm*square meter | / | 1.2 |

| (SG**W)Light Transmittance | % | GB/T 2410 | 60±3 |

| (SG**HT)Light Transmittance | % | GB/T 2410 | 79±5 |

| Haze | % | GB/T 2410 | 94±3 |

| Tensile Yield Stress | Mpa | GB/T 1040 | ≥55 |

| Nominal Strain of Tensile Fracture | % | GB/T 1040 | ≥60 |

Tensile Modulus of Elasticity | Mpa | GB/T 1040 | ≥2200 |

| Notched Impact Stength of Simply Supported Beam | Mpa | GB/T 1043 | ≥ |

| Tensile Impact Stength | Mpa | GB/T 13525 | ≥150 |

| Change Rate of Heating Size | % | JG/T 347 | ≤10 |

| Thermal Deformation Temperature | ℃ | GB/T 1634 | 135 |

| Coefficient of line Expansion | ℃-1 | JG/T 347 | 3.5×1010^(-5) |

| Combustion Performance | / | GB 8624 | B1 |

| Flame Retardant Performance | / | UL94 | V2/V0 |

| UV Transmittance | % | GB/T 2680 | 0 |

Outdoor LED light box, Advertisment Sign,Lampshade.

Background lanp sign,Commnucation Channel,Felexible Mirror

Protection Screen,Advertising Shutter etc

1.How long do the polycarbonate sheets last?

Polycarbonate hollow sheets warranties against most types of failures. The life expectancey can be as much as 10 years,depending on professional installation practice and enviromental factors like air pollution,winds,and erosion by sand particles.

2.How do i cut these sheets?

Polycarbonate hollow sheets may be cut with eigher a circular sa better to cut a few sheets at time to reduce vibration

Also,if using toothed circular saw blade,better results may be seen running the blade backwards.Sheets may also be cut by hand by carefully using tin snips or a utility knife.For further information please refer to our pdocuts manuals.

3.What should I sue to clean my panels.

Warm water with a mild household detergent should be sufficient to clean polycarbonate hollow sheets.Wipe off any remained dirt with a soft cloth and wash again.Never use a solvent based cleaner(ammonia,etc).AVOID using sponges or brushes that can scratch the sheets surface.

4.My building inspector says i need to know your flame spread rating

Can you prvodie this information?

Yes,we can provdie test reports and other such documents.

5.Does polycarbonate hollow sheets really have anti UV coating?

Yes, our panles with has UV coating 80 μm. It maks the polycarbonate sheets a perfect barrier against the harmful

Contact |

Salesmanager | Austin Xiao |

Cell /Wechat | +86- |

| +86 |

Tell | 86-574-62211527 |

Fax | 86-574-62058398 |